Hot Forming

INNOVATIVE HOT FORMING FOR AUTOMOTIVE LIGHTWEIGHT Technology

In the automotive industry, we face the challenge of reducing vehicle weight without compromising on safety, performance, and functionality. Hot forming, also known as press hardening, is a key technology to make vehicles lighter and thus more fuel- and energy-efficient, while simultaneously reducing CO2 emissions and environmental impact. Our advanced hot forming technology supports customers in achieving these ambitious goals.

CUSTOMIZED HOT FORMING

Press Hardening Solutions for Every Heat Treatment Type

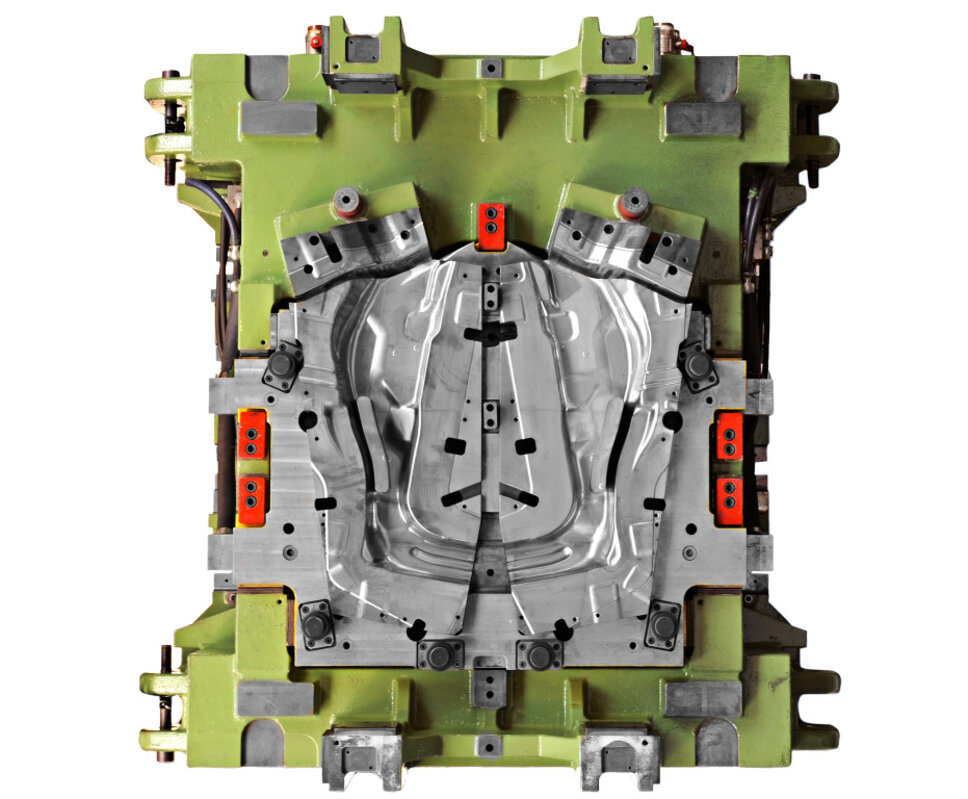

With our comprehensive experience, we are leaders in the manufacture of hot forming tools for ultra-high-strength steels and aluminum. We offer a wide range of hot forming processes, including Tailor Welded and Tailor Rolled Blanks, Patchwork Technique, and Tailored Tempering, to meet the demanding standards of automotive lightweight construction. Our processes are optimized through advanced tool design, sensor technology, efficient cooling systems, and high-quality materials.

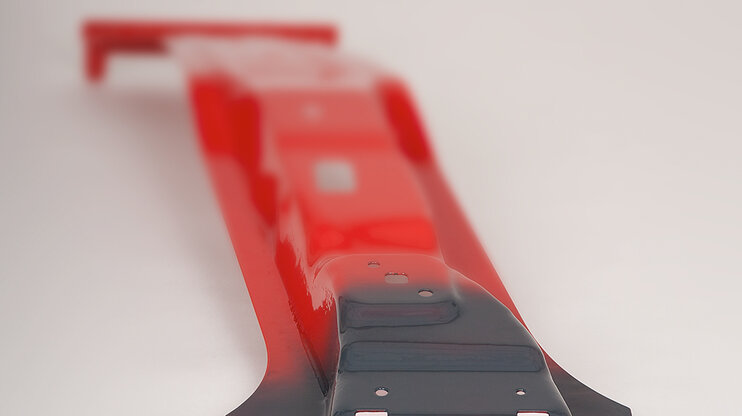

OPTIMAL COMPONENT PROPERTIES THROUGH TAILORED TEMPERING

A Revolution in Hot Forming

Tailored Tempering, known as SoftZone, enables the targeted adjustment of properties in metal parts. This advanced technique revolutionizes hot forming by allowing different strengths and ductilities within a component, leading to exceptional crash performance. We are pioneers in the field of Tailored Tempering and offer leading solutions through our years of expertise.

The Next Generation of Efficiency in Hot Forming

Through our ongoing research in hot forming, we have developed SoftZone 2.0, which allows more precise temperature control by managing each heating cartridge. This simplifies troubleshooting in the event of heating cartridge failures and ensures seamless continuation of operations. With SoftZone 2.0, we are pushing the boundaries of hot forming to provide our customers with top-tier solutions that enhance production efficiency and meet customized component requirements.

SMARTTOOLS

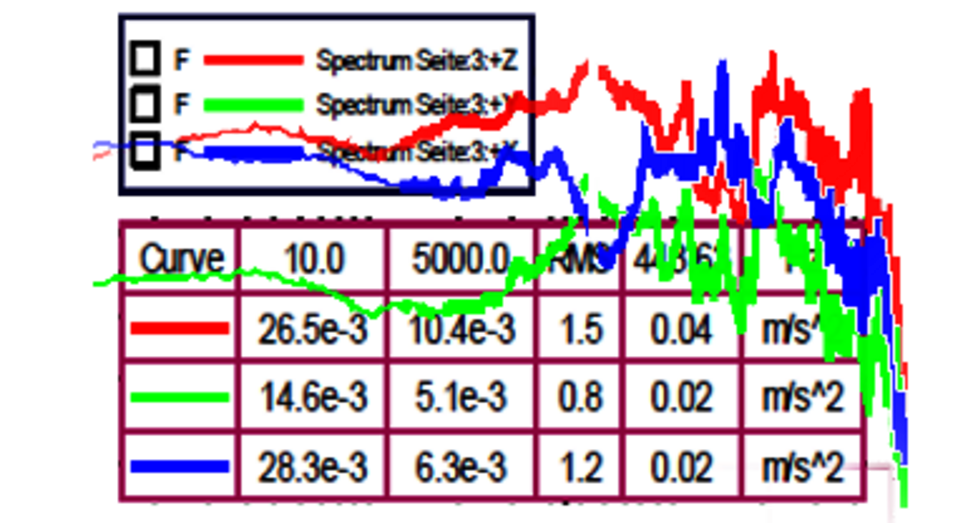

Process Monitoring and Quality Control in Hot Forming

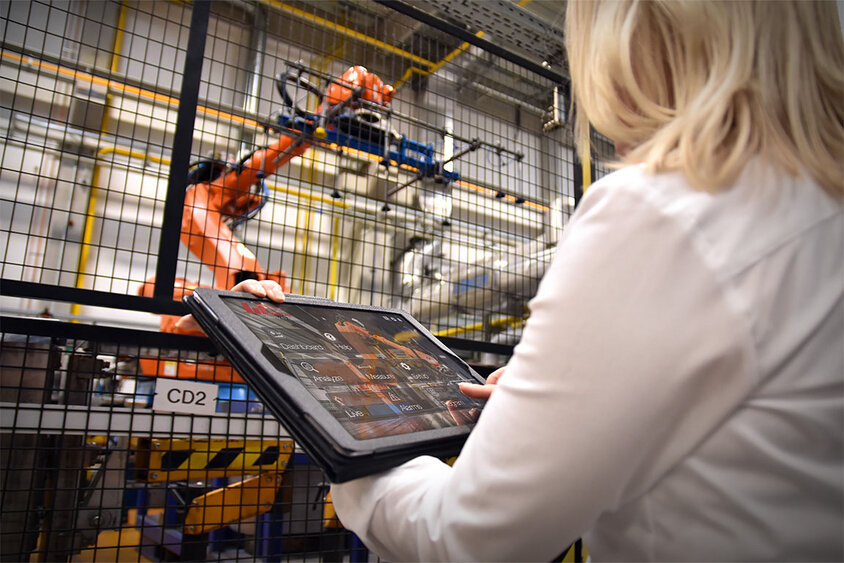

Our innovative SmartTools leverage machine learning to ensure 100% control over produced components in terms of material quality and geometry. Equipped with cutting-edge sensor technology, they precisely measure pressure on active components, tool temperature, structural sound, and tool wear during hot forming. This enables unparalleled quality control and seamless process monitoring in hot forming applications.

SPECIALISTS FOR HOT FORMING SOPHISTICATED OF DOOR RINGS

Ideal Production Environment for Big Projects

Our automated system, equipped with a 1,600-ton press and a table size of 4 meters, is ideal for producing complex hot-formed door rings from various materials, thicknesses, and grades. We manage the entire production process, from blank manufacturing and patching to precise measurement in vehicle position. Additionally, we integrate innovative Tailored Tempering technology into our door rings, creating components with customized properties. At weba, quality, precision, and reliability are our top priorities, making us your ideal partner in hot forming.

OUR SPECIALTIES in Hot Forming

News: The World of Hot Forming

Blog: Insight into Hot Forming Technology

FAQs on Hot Forming

Hot forming, also known as press hardening or form hardening, is a manufacturing process in which metal sheets are formed at temperatures above the recrystallization temperature. The specific temperature varies depending on the metal type, typically ranging between 40% and 60% of the metal's melting point. Unlike cold forming, where material is processed at room temperature, hot forming allows for the creation of more complex and precise shapes with higher strength due to improved ductility, making the material more malleable and formable through heating.

The recrystallization temperature is the temperature at which a deformed metal is treated to restore its original crystal structure, which was altered by mechanical processes like rolling, drawing, or forging. During recrystallization, new stress-free crystallites grow and replace the deformed structures, reducing internal stresses and increasing the material's ductility.

Typically, the recrystallization temperature is around 50% to 60% of the metal’s melting point, measured in Kelvin. This process is crucial for restoring metal properties and improving workability after deformation.

The recrystallization temperature of a metal depends on its specific composition and prior treatments. Typically, it ranges between 1/3 and 1/2 of its absolute melting temperature (measured in Kelvin). For example, for steel with a melting point of approximately 1500°C (or 1773 Kelvin), the recrystallization temperature usually falls between 450°C and 700°C. However, this can vary depending on the alloying elements present and the processing history of the steel. Recrystallization temperatures are crucial for processes like annealing, where heating is used to reduce the stresses and hardness caused by cold working.

Typically, high-strength steel alloys are used for hot forming, where the material is shaped at high temperatures and then rapidly cooled (quenched) to achieve high strength. Currently, boron-alloyed quenched and tempered steel 22MnB5, also known under trade names like BTR 1650 and Usibor 1500, is widely used in deep drawing of automotive parts. This manganese-boron steel is known for its high tensile strength, starting at around 500 MPa and increasing to up to 1,650 MPa through the press hardening process, making it ideal for safety-critical and high-load automotive components.

Hot-formed components achieve their exceptional strength through a specialized manufacturing process. This process starts by heating the steel sheet, which has a ferritic-pearlitic microstructure, to temperatures of around 900 to 950°C. This heating transforms the steel into an austenitic microstructure, making it more formable for shaping complex geometries.

After forming, the sheet is rapidly cooled (quenched) in a specially designed tool. This quenching process converts the microstructure into a hard martensitic phase, which is responsible for the high strength and toughness of the final product, ideal for automotive applications.

Hot forming offers several advantages, especially in industries with high demands on material strength and precision, such as the automotive industry.

Key benefits include:

- Increased Strength and Durability: The process creates a martensitic microstructure, enhancing hardness and wear resistance.

- Complex Geometries: Allows the production of complex shapes not possible with cold forming.

- Reduced Internal Stress: Minimizes internal stresses, improving structural integrity.

- Lower Springback: Greater shape accuracy due to reduced springback.

- Efficiency: Combines multiple processes, optimizing material usage and reducing post-processing steps.

- Improved Ductility: Reduces risk of cracks during forming.

During the heating of steel in hot forming, various processes occur that influence its mechanical properties:

-

Recovery: At moderate temperatures (below the recrystallization temperature), some lattice defects caused by deformation are reduced, decreasing internal stresses in the material.

-

Recrystallization: Above the recrystallization temperature, new, undeformed grains form, making the steel softer and more ductile.

-

Phase Transformations:

- Austenitization: Between ~723°C and 910°C, the ferritic-pearlitic structure transforms into austenite, which can dissolve more carbon.

- Martensite Formation: During rapid cooling, the austenitic steel forms martensite, a very hard and brittle phase with a needle-like structure.

-

Grain Growth: Prolonged holding at high temperatures can lead to larger grains, reducing the steel's strength and toughness.

-

Precipitation and Alloying Effects: Different alloying elements may precipitate at high temperatures, hardening or embrittling the material.

-

Diffusion: High temperatures accelerate diffusion processes, homogenizing alloy elements and eliminating segregations.

These processes are intentionally utilized in heat treatment to achieve the desired properties in steel through methods such as hardening, tempering, annealing, or normalizing.

Austenitic steel is a type of stainless steel known for its excellent corrosion resistance and ductility. Here are the key properties of austenitic steel:

- High Chromium and Nickel Content: Austenitic steels typically contain high levels of chromium and nickel, which give them excellent corrosion resistance.

- Non-Magnetic: In the fully austenitic state, these steels are generally non-magnetic, which can be advantageous in certain applications.

- Good Formability: They are easy to form and process, making them ideal for various manufacturing processes.

- Excellent Weldability: Austenitic steels can be welded well without being prone to cracking or other welding defects.

- High Toughness: They maintain good toughness even at very low temperatures, making them suitable for cryogenic applications.

- Heat Resistance: Austenitic steels can withstand high temperatures without losing their mechanical properties, making them ideal for applications that require high operating temperatures.

This combination of properties makes austenitic steel a popular choice in hot forming as well as in industries such as automotive, food processing, medical technology, architecture, and the chemical industry.

Austenite is a phase or crystal structure in steel and other iron alloys that forms at high temperatures, such as during hot forming. This structure is face-centered cubic (FCC) and is characterized by a high number of slip planes, giving the material good ductility and toughness. Austenite typically forms when steel is heated above the A3 temperature (the temperature at which ferrite transforms into austenite) and is not stable at room temperature in pure iron-carbon alloys. However, it can be stabilized at lower temperatures by adding alloying elements such as nickel, manganese, or nitrogen, as is the case in many stainless and high-alloy steels. Austenite is especially important in the production of austenitic stainless steel, which provides high corrosion resistance and excellent mechanical properties.

Properties of Austenite:

-

High Ductility and Toughness: Austenitic structures can stretch significantly before breaking, making them very tough and formable, which is advantageous in applications requiring high mechanical stress.

-

Non-Magnetic: In its pure state, austenite is non-magnetic, making it useful in electrical and electronic applications where magnetism is undesirable.

-

Good Corrosion Resistance: Austenitic steels offer excellent corrosion resistance due to their high chromium and nickel content, making them suitable for many chemical and corrosive environments.

-

Good Weldability: Due to their high toughness and ductility, austenitic structures are easy to weld and less prone to cracking compared to other steel phases.

-

Cryogenic Properties: Austenite remains tough and strong even at very low temperatures, making it ideal for cryogenic applications where many other materials become brittle.

-

Heat Resistance: Austenite retains its mechanical properties at high temperatures, making it suitable for applications such as high-temperature furnaces and engines.

Quenching steel after heating to the hardening temperature is necessary in hot forming to quickly transform the austenitic structure of the heated steel into martensite. This process increases the hardness and strength of the steel by preventing the formation of softer phases like ferrite or pearlite. Rapid cooling locks the atoms into an over-structured, hard form, making the material ideal for high-stress applications.

Besides the automotive industry, hot forming is also used in the aerospace, construction, and consumer goods industries—anywhere high strength and complexity of components are required.