Parts Production

Quality-assured parts production and prototype parts

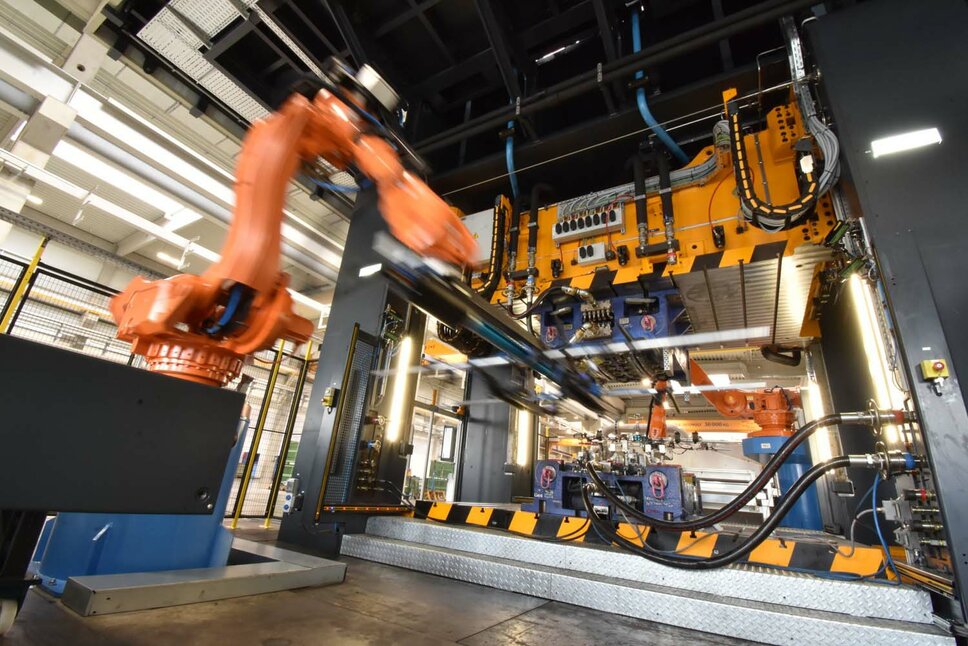

Our manufacturing capabilities include advanced hydraulic presses, with which we produce complex structural parts from a variety of aluminum and steel materials. Our modern press hardening lines offer the possibility to manufacture large and demanding hot-formed components in series. Depending on your parts production requirements, we use multi-level chamber furnace or roller hearth furnace technology to meet your specific needs.

Series production: Quality in Quantity

In the parts production weba stands as your reliable partner, especially in hot forming of series parts. With our state-of-the-art Press Hardening Lines, which have a pressing force of 1,600 tons, we are capable of precisely forming extensive and complex components from a variety of materials, thicknesses, and quality grades. By integrating Tailor Tempering Technology into our manufacturing processes, we are able to produce components with variable strength zones, tailored exactly to your individual needs in terms of crash safety and lightweight construction.

Prototype Production: High Efficiency even at Small Quantities

In addition to series production, we also offer the manufacturing of prototype components. For maximum flexibility and precision, we utilize state-of-the-art hydraulic presses with an impressive pressing force of up to 2,500 tons. With these machines, we can efficiently and precisely produce even complex structural parts in small quantities. Whether it involves aluminum, high-strength steels, or other common materials, we guarantee the highest quality and reliability in every step of parts production.

Certified Quality in Parts Production: Our Commitment to Excellence

We are committed to innovative manufacturing processes and strict quality controls in parts production to ensure that each component precisely meets your specific tolerance requirements, whether it's for series production, prototype development, or pre-production.

Replacement press for your parts production: Maximum production reliability.

For additional security in your parts production, we also offer our machines as replacement presses. This way, in the event of an unexpected failure, you have an immediate and reliable alternative on hand, allowing you to continue your parts production without delays. This not only helps you avoid costly downtime but also potential delivery delays to your customers. With our replacement presses, you ensure a smooth parts production process and increase the efficiency and reliability of your entire manufacturing line.