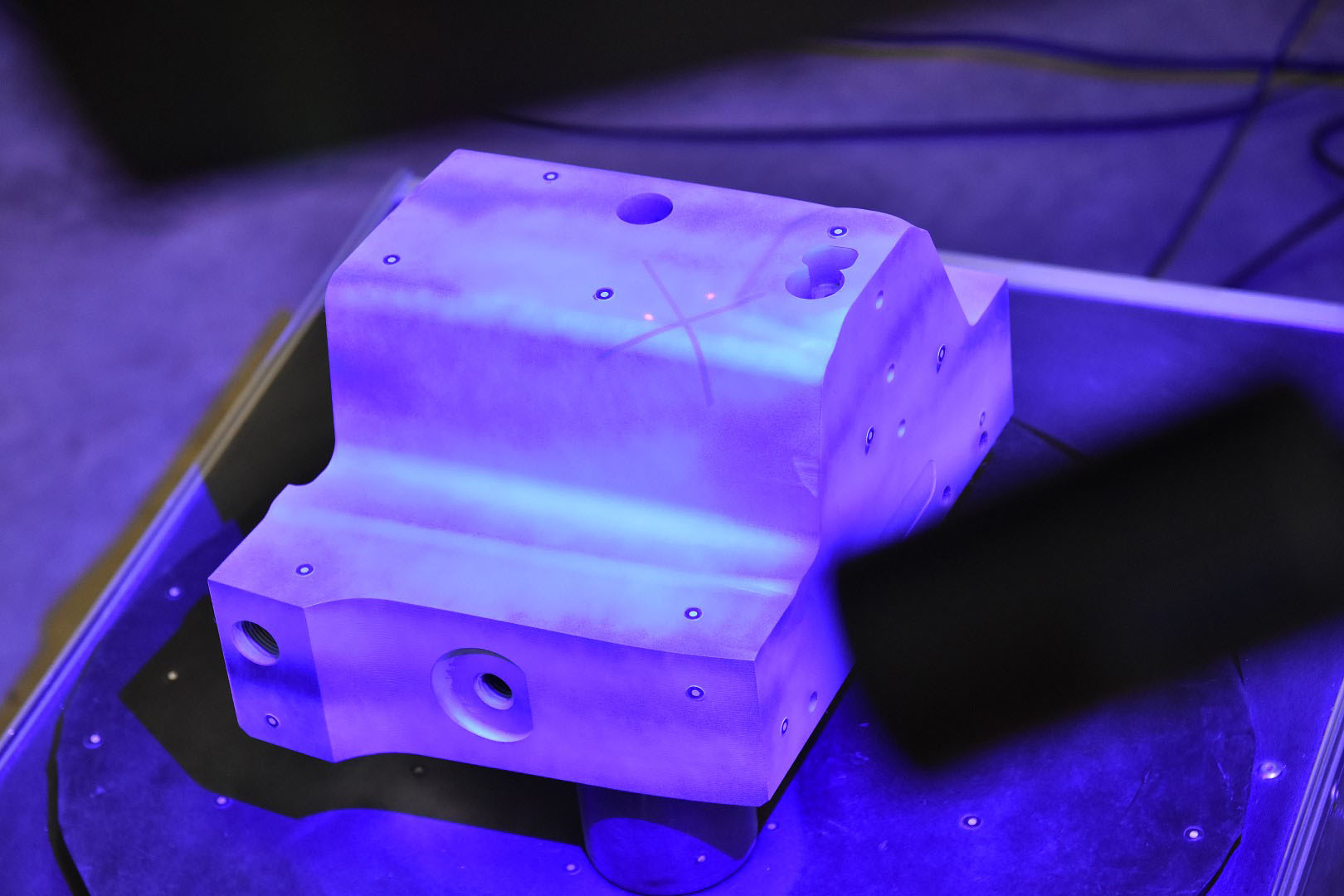

Year after year, the requirements for quality assurance in the automotive industry have become more demanding. What began with a simple measurement report has evolved into increasingly precise quality investigations over time. In response to these challenges, weba continuously modernized its processes, increasingly relying on digital technologies. A key milestone was the introduction of mobile 3D scanners, which enabled digital capture and analysis of stamping inserts. This technology ensures accurate data tracking and supports high-quality production of spare parts. The logical next step was the establishment of a state-of-the-art quality laboratory, equipped with the latest technology for mechanical material testing and metallographic analyses.

Introduction of Digilab for More Efficiency

Now, weba has taken another step towards efficiency and precision with the introduction of DigiLab. Developed by Meprotec GmbH, a long-standing partner of weba, DigiLab uses cutting-edge artificial intelligence to analyze various data sources and create automated reports. From images to test reports to logs - DigiLab automatically synchronizes information with the measurement data from the testing machines to create a seamless and comprehensive quality report.

Global Data Access and Integrated Alarm Routines

Thanks to DigiLab, productivity in the weba laboratories has been significantly increased. The system automates the data collection process and enables advanced error analyses and statistical evaluations. These digitalization measures eliminate manual processes and allow global data access, ensuring continuous monitoring and traceability of quality. Integrated alert routines immediately notify of any deviations in quality.

The implementation of DigiLab is further evidence of weba's commitment to continuous improvement and innovation.

About weba

Since 1982, weba Werkzeugbau has been known for its specialized solutions in the manufacturing of tools for cold and hot forming, earning an excellent reputation through innovation and quality. With locations in Austria, the Czech Republic, and Germany and over 300 dedicated professionals, the company develops customized, technologically advanced solutions for forming technology and lightweight construction.