Technological Innovation and Sustainability: A Look Back at 2024

Securely Into the Future – Certified to the Highest Standard

A significant achievement for weba Werkzeugbau was its certification according to DIN ISO 45001, highlighting its commitment to occupational safety and health management at the highest level. This certification underscores the company’s consistent adherence to modern standards for safe and health-promoting workplaces.

Technology and Digitalization in Focus

The year 2024 for weba Werkzeugbau was marked by digital transformation and technological advancement:

-

SmartTools Leading the Way: weba Werkzeugbau established itself as a pioneer in intelligent, sensor-controlled forming tools. These innovations ensure high-quality component production, optimized process control, and improved efficiency in customer projects.

-

3DEXPERIENCE ONCLOUD: With the upgrade to this globally connected platform, the company elevated its digital infrastructure to a new level. Teams now collaborate more efficiently, seamlessly, and across locations—a significant step toward modern collaboration.

-

DigiLab – Artificial Intelligence in Action: The introduction of a state-of-the-art digital lab marked a major milestone in data analysis. Automated reporting, precise error analysis, and statistical evaluations are just some of the benefits achieved through AI technology. These advancements not only boost productivity but also enable well-informed decision-making on a global scale.

New Horizons in the Automotive Sector: weba Explores Innovative Market Opportunities

With an expanded portfolio, weba Werkzeugbau reinforces its role as a forward-thinking partner in the automotive industry. The company’s entry into the production of underride protection components and its innovative roll bonding technology mark another milestone in its development.

-

Underride Protection: High-Tech for Premium Electric Vehicles

As part of Audi and Porsche's PPE platform (Premium Platform Electric), weba Werkzeugbau delivers tailored solutions. These include both press tools and highly precise trimming tools for composite components, meeting the highest standards of durability and precision. -

Roll Bonding: Efficiency and Innovation in Battery Technology

Roll bonding involves permanently joining two aluminum sheets through an advanced rolling process, followed by targeted inflation. This technique not only improves battery cooling but also enhances the structural rigidity of battery elements.

Both applications present new challenges for tool manufacturing. The specific demands of composite components and aluminum compared to steel require innovative technical solutions. This is precisely where weba excels—with expertise, precision, and a clear focus on the future of mobility.

Entering the Energy Future

One of the most exciting developments was weba's entry into the energy market. By producing high-precision tools for bipolar plates, weba contributes significantly to sustainable technologies such as fuel cells and electrolyzers. These key components play a vital role in hydrogen production, reinforcing the company's commitment to actively shaping an environmentally friendly future.

A look into the future

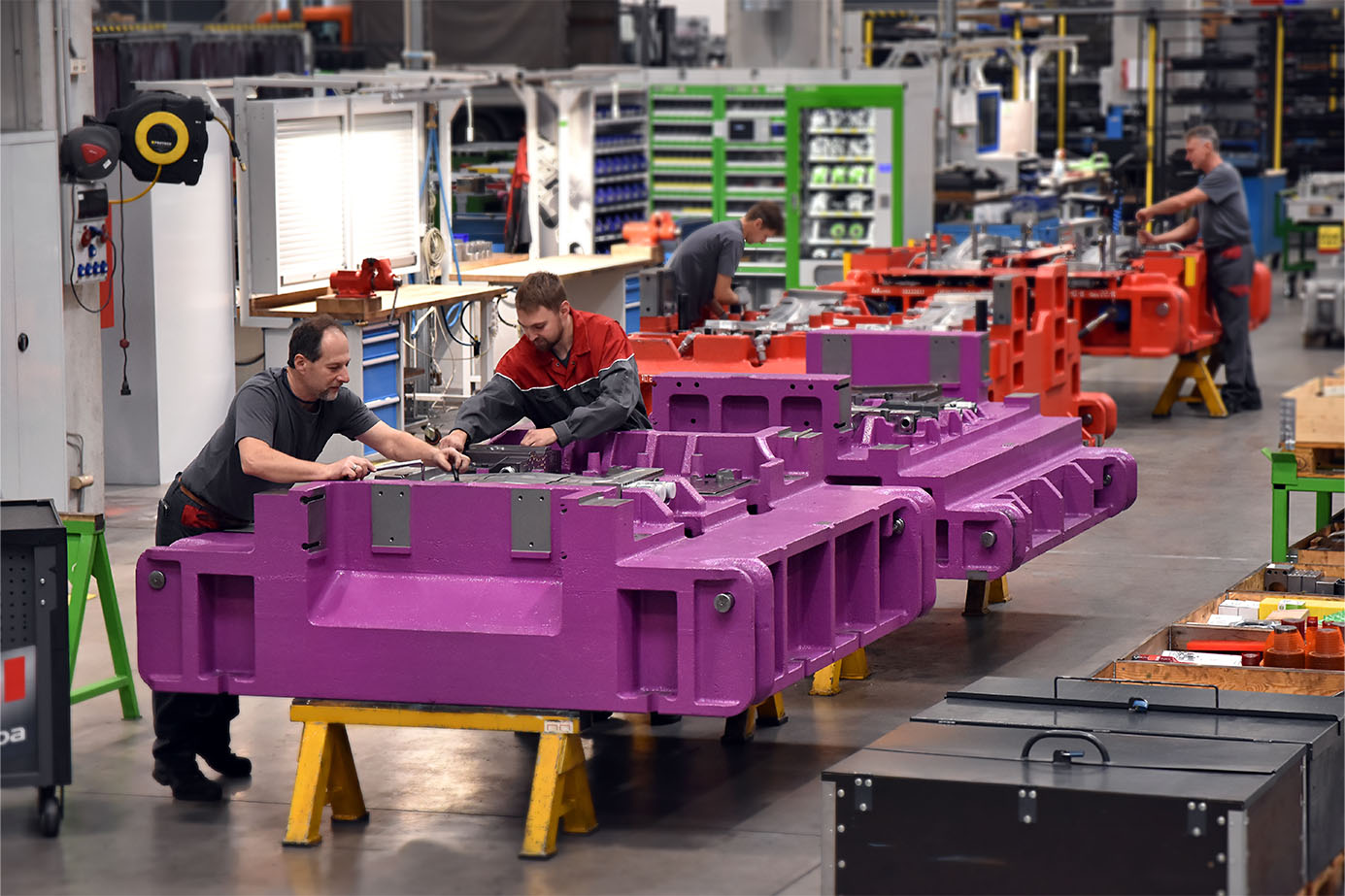

An Attractive Employer for the Best in the Industry

With these remarkable achievements, weba Werkzeugbau positions itself not only as a leader in innovation but also as an attractive employer for skilled professionals. The company offers a modern working environment, exciting future-oriented projects in forming technology and renewable energy, and the opportunity to be part of a team shaping the industry of tomorrow.

Shaping the Future: Technological Excellence Aligned with Sustainability

Focusing on sustainable technologies and the ongoing development of complex hot forming tools, weba Werkzeugbau looks to the future with optimism. Expanding its expertise in renewable energy is not just a strategic goal but also a clear commitment to the responsibility owed to future generations.

About weba Werkzeugbau Betriebs GmbH

Since its establishment in 1982, weba Werkzeugbau has been a leader in the development and production of cold and hot forming tools. At its locations in Austria, the Czech Republic, and Germany, more than 320 highly qualified employees combine cutting-edge technology with extensive expertise. The result is customized, innovative solutions that meet the highest quality standards. As a trusted partner for OEMs and Tier 1 suppliers in the automotive industry, weba sets new benchmarks in precision and innovation.